Copper foil tape can be a cornerstone of contemporary electronics, shielding, and Do-it-yourself innovation. But how does this hugely conductive, flexible substance go from Uncooked copper ore on the essential rolls found in labs, factories, and toolboxes all over the world? Let’s get a more in-depth consider the production course of action, Attributes, and importance of copper foil tape.

## The Production Approach: Bit by bit

**1. Copper Extraction and Refining**

The journey commences with copper ore, which is mined after which refined via a series of ways—crushing, grinding, flotation, smelting, and Adhesive Copper Foil electrolysis—to achieve a purity of approximately ninety nine.99%[1][4][five]. This high-purity copper is essential to the tape’s electrical Homes.

**2. Making Copper Foil**

There are 2 major approaches for making copper foil:

- **Electrolytic (Electrodeposited) Copper Foil:** Copper is dissolved in an electrolyte and deposited onto a rotating drum as a skinny layer, letting exact Management in excess of thickness (from 5 to two hundred micrometers)[one][4][six][7]. This method is widely used for electronics, especially printed circuit boards (PCBs).

- **Rolled Annealed Copper Foil:** Thick copper sheets are mechanically rolled to micrometer thickness, then annealed for flexibility and ductility. This technique yields a smoother floor, ideal for adaptable circuits and apps wherever malleability matters.

**three. Area Procedure and Ending**

Just after rolling or electrodeposition, the copper foil undergoes treatment plans for instance annealing (to boost ductility), surface area cleansing, and often coating or plating to improve corrosion resistance and adhesion[one][4][seven].

**4. Adhesive Application**

A key element of copper foil tape is its adhesive backing. The copper foil is coated that has a conductive or non-conductive adhesive—generally acrylic or rubber-primarily based—picked out for its solid tack and ability to keep up conductivity. The adhesive is evenly applied, then dried and cured for longevity[2][five][six].

**5. Slicing and Packaging**

The finished foil is slit into rolls or sheets of varied sizes, then inspected for good quality—checking thickness, conductivity, and adhesion—right before packaging for shipment[5][6].

## Homes That Power Effectiveness

Copper foil tape is prized for its:

- **Exceptional electrical and thermal conductivity**—important for shielding, grounding, and circuit repairs[four][five][six].

- **Corrosion and heat resistance**—making it trusted in severe environments[two][six].

- **Potent adhesion**—making certain it bonds tightly and resists peeling[2][6].

- **Versatility and workability**—allowing for it to conform to irregular surfaces and become easily Reduce or shaped[4][5].

## Varieties of Copper Foil Tape

| Form | Output Method | Important Characteristics & Takes advantage of |

|----------------------------------|--------------------------|-------------------------------------------|

| Electrodeposited Copper Foil | Electrolytic deposition | Uniform thickness, high conductivity, PCBs|

| Rolled Annealed Copper Foil | Rolling & annealing | Flexibility, smooth surface, adaptable PCBs|

| Superior-Temperature RA Copper Foil | Extra warmth cure | Improved heat resistance |

| Ultra-Slender Copper Foil | Precision rolling/depo. | RFID tags, smart playing cards, microelectronics |

## Environmental Criteria

Copper foil generation is Electricity-intense, with important Double Sided Copper Tape carbon emissions. One example is, making one particular ton of copper needs about 220 GJ of Power and generates two.2 tons of CO₂[1]. Recycling copper significantly minimizes Electrical power use—down to only twenty% of Major production—and lessens environmental affect[1].

## The importance of Copper Foil Tape

From shielding sensitive electronics to enabling Resourceful DIY jobs, copper foil tape is actually a testomony to Superior producing and material science. Its journey—from ore to ultra-slim, adhesive-backed tape—reflects the two technological development and the ongoing challenge to harmony innovation with environmental obligation.

As need for electronics, renewable Electrical power, and electric cars grows, copper foil tape will remain a vital content—pushed by both its special Houses and the evolving strategies made use of to provide it proficiently and sustainably

Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Taran Noah Smith Then & Now!

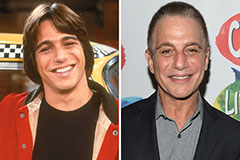

Taran Noah Smith Then & Now! Tony Danza Then & Now!

Tony Danza Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!